Medaarch (insieme a Sautech ed Enco) è coinvolta nel progetto EasyPRINT (Engine for the Assessment of SYStem PRINTing), che ha indirettamente ricevuto finanziamenti dal programma d’azione di ricerca e innovazione Horizon 2020 dell’Unione Europea, tramite la Open Call #2 di KYKLOS 4.0 ed eseguito nell’ambito del progetto KYKLOS 4.0 (GRANT n. 872570). EasyPRINT fornisce un semplice servizio di progettazione intelligente per sviluppare prodotti personalizzati seguendo un processo rispettoso dell’ambiente.

Medaarch (together with Sautech and Enco) is involved in the project EasyPRINT (Engine for the Assessment of SYstem PRINTing), that has indirectly received funding from the European Union’s Horizon 2020 research and innovation action programme, via the KYKLOS 4.0 Open Call #2 issued and executed under the KYKLOS 4.0 project (GRANT n. 872570). EasyPRINT provides an effortless smart design service to develop personalised products following an environmentally friendly process.

THE PROJECT

The project to be developed would allow Medaarch, the industrial partner of the consortium, to offer its customers a pre-evaluation service for the costs and the product they need through additive printing technologies. In fact, Medaarch as owner of the Center for Digital Handicraft, incubator of innovative manufacturing companies, offers as its services those rapid prototyping carried out through a fleet of 3D printers (of various technologies and formats, sla, fdm, stereolithography, etc.) which is the owner. Today Medaarch adopts the following workflow which includes the following steps:

1) the acquisition of the 3d file by the customer;

2) Any editing of the same for customization needs expressed by the customer;

3) the slicing test for the evaluation of the most suitable 3d printing technologies for product printing;

4) the evaluation of the material best suited to the customer’s needs and the morphological characteristics of the product to be printed;

5) the estimate in terms of cost of the various technology / material combinations.

Like most European 3D printing centers, Medaarch also consumes a lot of time in terms of human resources to offer its services. For this reason, the consortium wants to create a web platform that allows the final customer of the industrial partner the possibility of:

a) customization of their 3D file in terms of size;

b) choice of the most suitable technologies;

c) choice of the most suitable material;

d) comparison of estimates;

e) evaluation of the impact on the press environment

f) Repository of personal files.

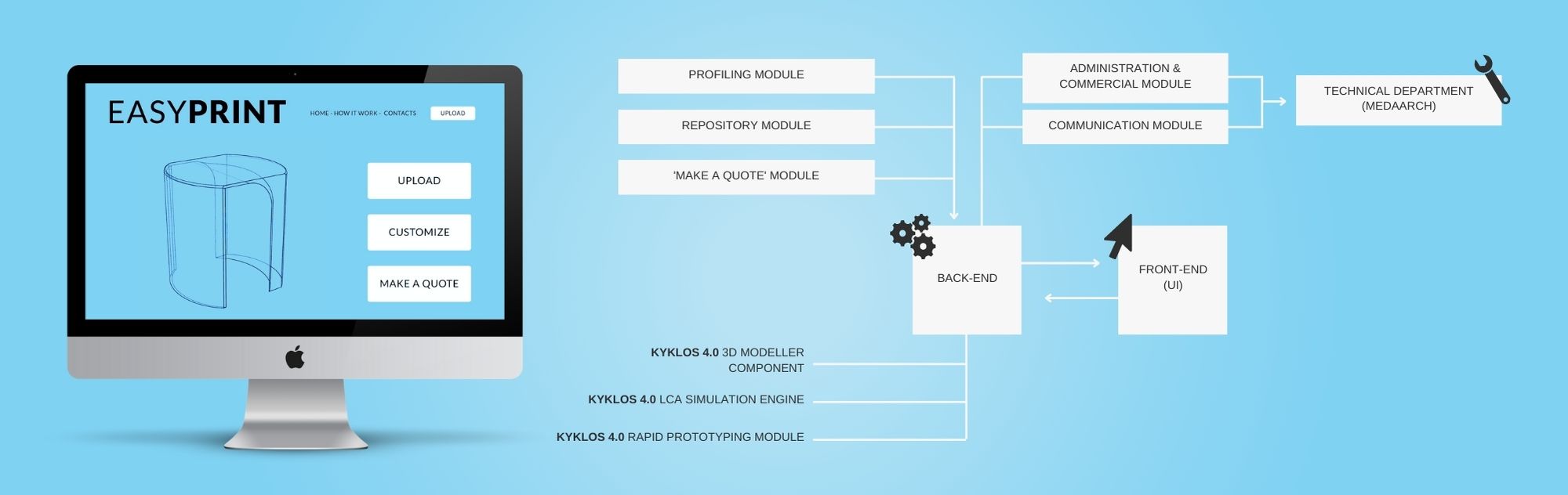

In order to create this platform, the consortium would develop a web application consisting of the following modules: 1) Module for Front end and access to the platform, user profiling and file upload; 2) product customization module created with the “Web 3D modeller component” developed by KYKLOS4.0; 3) module for the evaluation of the technologies and the most suitable material and 4) module for the quantification of the material needed for printing with the “Rapid Prototyping Module” developed by KYKLOS4.0; 5) economic and comparative evaluation form of the various printing hypotheses; 6) Form for sending the file and product validation to the service department of the Medaarch company; 7) file repository module to allow the customer not to lose the print evaluations carried out on the platform. 8) Form to return to the customer an alert on the environmental impact that the product printing would have in terms of CO2 production created with the “LCA Simulation Engine” developed by KYKLOS4.0.

The platform created by the consortium would significantly increase the speed of the workflow of the Medaarch company and at the same time would promote an awareness of end users towards the issue of climate change by suggesting prints with more sustainable materials. Furthermore, through the use of the functions present within the “Rapid Prototyping Module” it would allow the industrial partner of the consortium to significantly reduce the quantities of raw materials in the warehouse.

ENCO will be in charge of all the activities related to technology adoption.

Sautech will be in charge of the development of all software modules, in particular it will be developed and debugged a) an human-centered interface will be developed, to facilitate the use of the platform by non-trained users; b) a set of communication libraries between the KYKLOS4.0 tools – customized SW modules. All the modules will be connected by network to the others: this means that the components of the final system can be remotely distributed.

Result are expected to be reached in the following two field

Advanced manufacturing system agility and interoperability:

- increment agility and speed: since the modelling process is make leaner, we expect to significantly reduce the time needed to complete the prototyping step;

- improve equipment digitization: data will be exchanged between the tools and the machines by the ethernet interface;

Information & Communication technologies:

- automatization of acquisition data: while currently data are manually inputted to tools and machines, the solution will interconnect all its main components;

FOLLOW EASYPRINT ON:

Condividi:

Ricerche simili